Quick Release Mooring Hooks

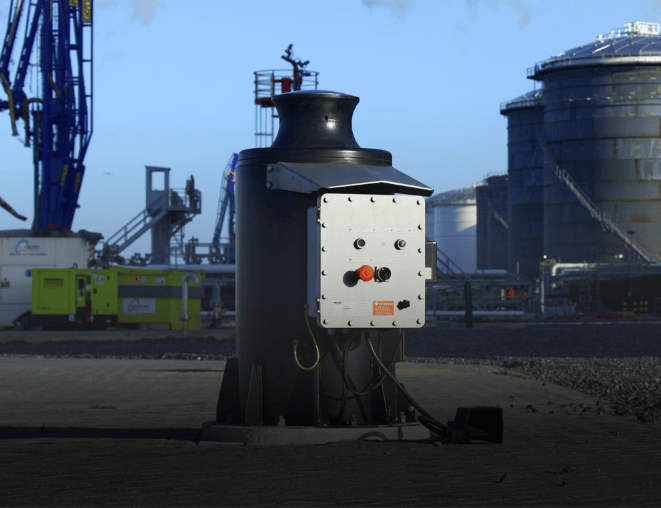

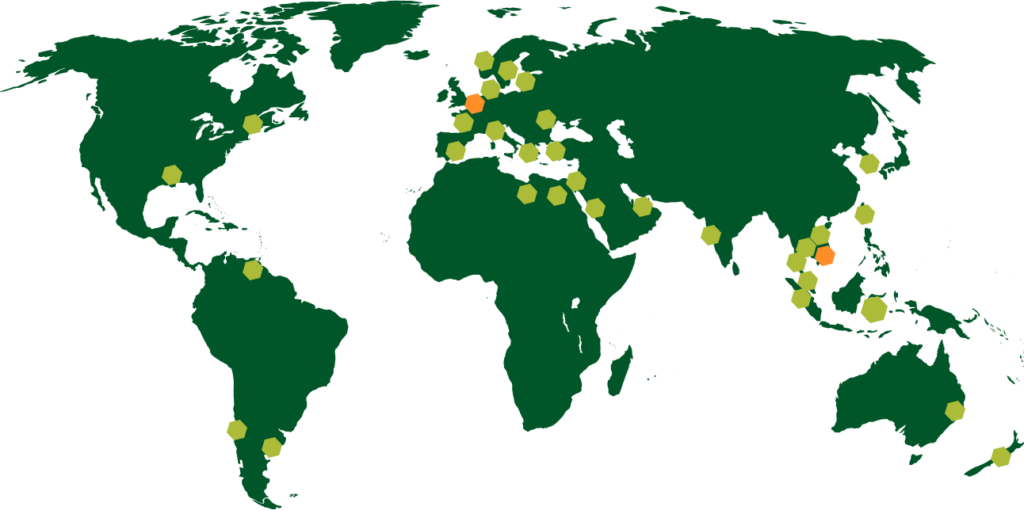

Straatman designs and manufactures quick release mooring hooks for ports, terminals and offshore facilities worldwide. Our systems enable safe, controlled release under load and support efficient mooring operations in demanding maritime environments.

Quick release mooring hooks can be configured with manual, electric or electro-hydraulic release, mooring load monitoring, and remote control functionality. As a result, operators maintain control, even under high loads or changing environmental conditions.

Built for Demanding Maritime Operations

For oil, gas, chemical and bulk terminals, our hooks support safe berthing and unberthing operations. Controlled release under load helps operators respond quickly when conditions change. Learn more about mooring hooks for jetties

Quick release offshore hooks FPSO & FSRU

For offshore, FPSO and FSRU vessels, Straatman supplies robust quick release hooks that support remote operation and reliable performance in harsh environments. Learn more about FPSO & FSRU solutions

Quick release mooring Hooks for LNG terminals

LNG terminals require reliable equipment that meets strict safety standards. Our hooks are designed for high loads and can be integrated with monitoring and control systems. Learn more about LNG terminal applications

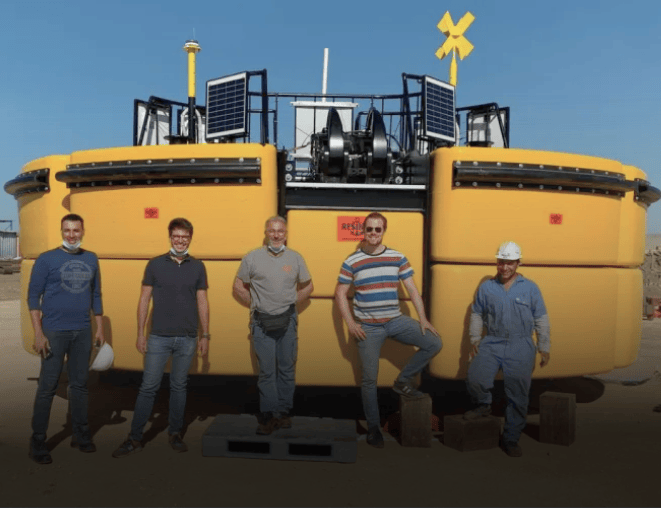

Mooring buoy quick Release Hook

We also provide integrated solutions for mooring buoy systems, including load monitoring and remote release functionality. Learn more about mooring buoy applications

Why quick release mooring hooks are essential

Today, vessels are becoming larger. As a result, mooring loads are increasing. At the same time, safety requirements across ports and terminals are becoming more stringent. Together, these developments place higher demands on mooring equipment used during daily operations.

Therefore, terminals need systems that allow operators to work safely and remain in control at all times. In addition, equipment must respond predictably, especially when conditions change or loads increase during mooring.

In practice, a quick release mooring hook secures a mooring line on a jetty, berth or offshore structure. When required, the hook releases the line quickly. Importantly, the system performs this release in a controlled manner and can do so while the line is still under load. As a result, operators reduce operational risk, prevent equipment damage, and improve protection for quay and terminal personnel.

Quick Release Hooks, proven Straatman quality

As a leading supplier of Quick Release Hooks, Straatman delivers systems that guarantee safe and efficient mooring operations across oil, gas, chemical, iron, coal, and grain terminals worldwide.

Configured for Your Operation

Every terminal is different. For this reason, Straatman supplies quick release mooring hooks that match operational requirements, vessel types and safety philosophies.

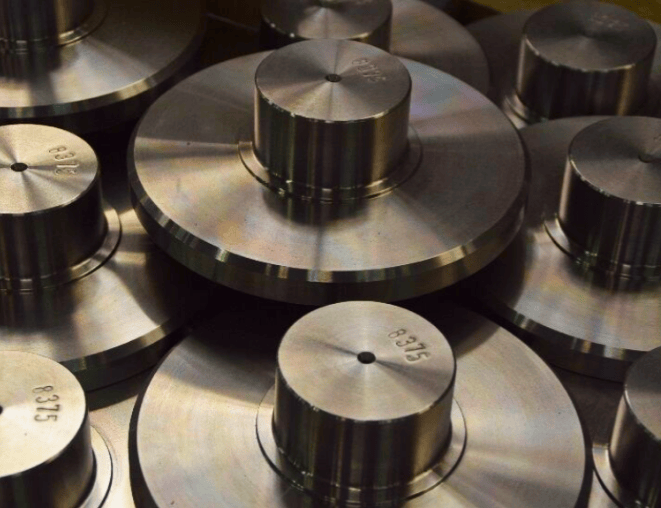

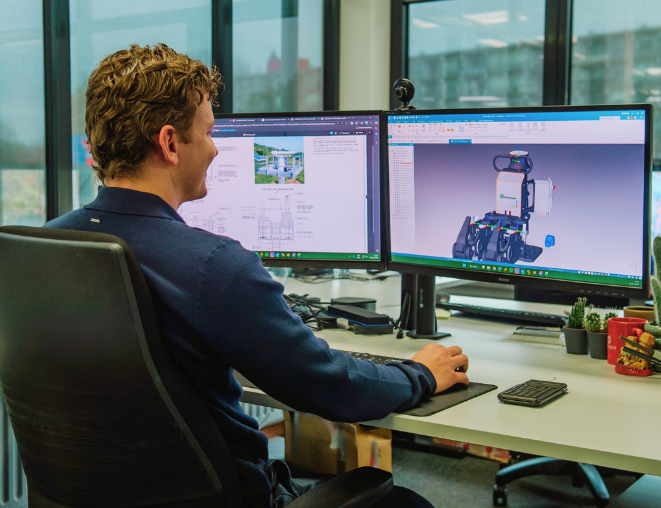

Designed, Built and Tested In-House

We design, manufacture and test all quick release mooring hooks in-house at our facilities in the Netherlands. As a result, we maintain full control over quality, tolerances and performance throughout the entire process.

Straatman Quick Release Mooring Hook

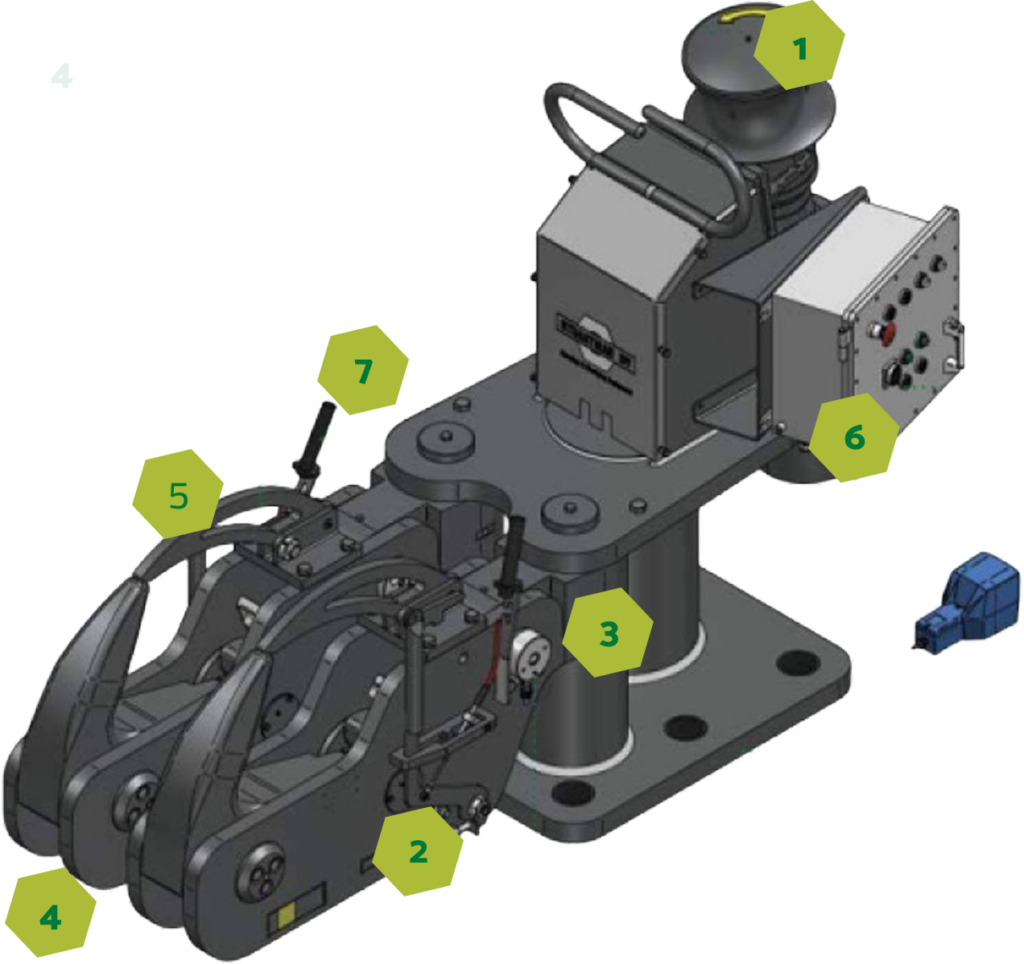

An example of our quick release mooring hooks including various options:

Integrated vertical capstan

The capstan allows hauling in of the mooring line in a safe and efficient way.

Remote release

All quick release hooks can be equipped with an electric or electric-hydraulic release mechanism.

Mooring load monitoring system

With inhook load cell calibration facility, locally and remote controlled ny our MoorControl software.

Self supporting

All hooks are self supporting. Movements are limited to prevent contact with the structure. The hook parts are made of forged steel and are counterbalanced.

Rope keepers

In some specific situations, there is a risk of the mooring rope slipping of the quick release hook. In order to avoid this risk a hook can be euiped with a rope keeper that prevents the rope from slipping

Explosion proof version components

For hazardous zone, in conformance with ATEX, IECEx and Class 1 division 2.

Manual release lever

All quick release hooks can be released manually with an effort +/- 20 kg at full load.

Base plate

The base plates are made of high quality steel. Custom made base plates to fit existing bolt patterns are available on request

Release Mechanism

Straatman offers a wide range of Quick Release Mooring Hook configurations and features. Straatman Quick Release Mooring Hooks are available with:

- Manual release

- Electric release

- Electro-Hydraulic release

This allows terminals to select the most suitable solution for their operational and safety requirements.

Key features

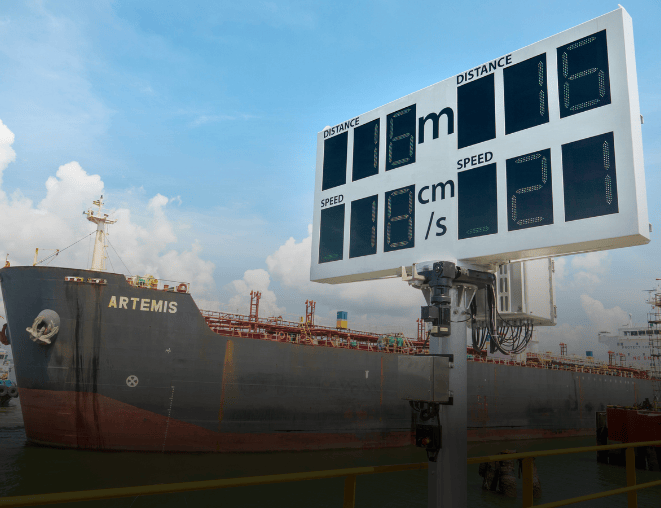

Mooring Load Monitoring

Straatman equips quick release mooring hooks with integrated load cells to measure mooring line loads. Operators view load data locally or remotely, which supports safer and better-informed mooring decisions.

Remote Control Operation

A remote control allows operators to release hooks from a safe location, such as a control room. This approach reduces personnel exposure and improves safety during critical mooring situations.

Additional Options

Depending on the application, the system can include:

– Rope keepers

– Integrated vertical capstans

– Custom foundations

– Explosion-proof components for hazardous areas

Safety, Testing and Compliance

Safety is the foundation of every Straatman quick release mooring hook.

Testing and Documentation

We test all hooks on our calibrated in-house testing machines to verify performance under load. Straatman includes standard test certificates with every delivery. If required, classification authorities can witness the testing process.

Hazardous Area Solutions

For hazardous environments, Straatman can supply certified electrical components. This ensures safe operation in compliance with project-specific requirements.

facilities in Holland

Our factory in Holland is our home base for design, engineering, production, and testing. This means that we can ensure the quality of our products and processes from start to finish. We are very proud of our unique ability to offer our clients this level of control and transparency.

We therefore invite our clients to visit our factory in the Netherlands. A factory visit offers a clear view of our production process and the way we build our products. It also demonstrates our ongoing commitment to quality, from first design to final testing.

What You Receive

Each Straatman quick release mooring hook system includes the following components:

- A fully assembled and tested hook system

- Control panels and electrical components (as applicable)

- User manuals and technical documentation

- Test certificates and quality records

In addition, our engineers can support installation and commissioning when required.

Traceability

Material traceability is a key part of our quality assurance process. We track all materials from purchase to final production to ensure consistent quality and safety. Straatman uniquely identifies, registers and marks each material and supplies the required material certificates. This approach enables us to deliver reliable products that meet customer and industry requirements.

Continuous Innovation

We continually innovate and develop new products and solutions. In fact, our team of dedicated engineers and developers is always working on improvements and new ideas. We regularly introduce new products and solutions to the market.

Your mooring project

Straatman supplies single and multi-hook mooring systems, including custom foundations and accessories.

- Custom Options Available – Add features such as electric-hydraulic release, load monitoring, remote control, or rope keepers.

- Tailored to Your Needs – Our engineers translate your requirements into robust, reliable mooring systems.

- Expert Support – From concept to commissioning, our team is ready to help you build the perfect mooring solution.

Download our Mooring & Berthing catalogue now

Our Mooring and Berthing Catalogue offers clear specifications, available options, and essential product insights.

Other mooring systems

We are your partner for your complete mooring system! We can integrate features such as:

FREQUENTLY ASKED QUESTIONS

A quick release mooring hook secures and releases a mooring line on a jetty, berth or offshore structure. Unlike conventional bollards, the hook releases the line under load and improves safety during normal and emergency operations.

A quick release mooring hook system provides controlled, safe, and efficient mooring for vessels in ports and terminals.

You mainly see these systems in . Oil and gas terminals, Chemical and liquid bulk terminals, Liquefied natural gas terminals, Dry bulk terminals (coal, ore, grain), Container and general cargo terminals amd Offshore jetties and single-point mooring locations. Typical reasons to use quick release hooks include improved safety, better operational control, faster mooring and unmooring, and the ability to release a vessel quickly in emergencies.

Yes. A quick release mooring hook releases a mooring line while it is still under tension, up to the hook’s rated capacity.

This capability is critical during emergency situations. In such cases, operators cannot gradually reduce line loads and must release the vessel quickly. Unlike manual release from a bollard, a quick release mooring hook enables controlled release from a safe distance and improves safety for quay personnel.

The safe working load (SWL) defines the maximum line load that a quick release mooring hook can safely hold and release.

Straatman supplies each hook with a defined rating, such as 100, 150 or 200 metric tonnes. The required capacity depends on vessel size, environmental conditions, mooring line layout and the results of the berth mooring analysis. When a unit includes multiple hooks, the total capacity equals the combined capacity of the individual hooks.

Quick release mooring hooks support configuration for each terminal or offshore facility. Common options include:

– Single, double, triple or quadruple hook units

– Manual, electric or electro-hydraulic release

– Local or remote release from a control panel

– Integrated capstans for line handling

– Load monitoring and system integration

– Custom foundations, coatings and explosion-safe versions

Yes. Straatman supplies quick release mooring hooks with certified components suitable for hazardous environments.

Where required, electrical and control components can be provided in compliance with applicable standards such as ATEX and IECEx. The final hazardous area classification and certification depend on the project-specific requirements and installation environment.

Straatman designs and tests quick release mooring hooks in line with the OCIMF Mooring Equipment Guidelines, 4th Edition (MEG4). These guidelines describe industry best practices for the safe design, testing and use of mooring equipment at tanker and gas terminals.

Final compliance always depends on the complete mooring arrangement and the project-specific requirements.

Straatman manufactures quick release mooring hooks from high-quality steel components and produces them in the Netherlands.

By controlling the process in-house, we ensure consistent quality, reliable performance and compliance with applicable international guidelines. Material selection and final specifications depend on the project requirements and operating environment

Straatman applies strict surface preparation and coating standards to ensure long-term corrosion protection.

As standard, surface preparation complies with ISO 12944, corrosion category C5M. We use coating systems supplied by Hempel, with RAL 9005 (black) as the standard finish. Alternative RAL colours or coating systems from approved suppliers such as International, Jotun or Sigma can be provided upon request.

In addition to quick release mooring hooks, Straatman supplies a complete range of mooring and berthing solutions, including:

– Berthing Aid Systems (Docking Aid Systems)

– Control panels

– Software solutions

– Environmental Monitoring Systems (EMS)

– Portable devices

– Smart bollards

Straatman integrates these systems to support safe, efficient and well-controlled terminal mooring operations.

News

Go to all newsLet’s discuss your mooring project

- High Quality Products

- Excellent Service

- Over 50 years of experience

- Certified on Every Level

es_ES

es_ES fr_FR

fr_FR pt_PT

pt_PT