What Is a Quick Release Towing Hook?

A quick release towing hook is a deck-mounted device that secures a towing line and allows it to be released quickly in a controlled manner.

Unlike conventional towing arrangements, a quick release towing hook supports release while the line remains under tension. This capability is essential during emergencies and improves overall safety for vessel crews.

Release Under Load for Emergency Situations

In emergencies, operators must release the towing line immediately. Straatman quick release towing hooks release under full tension, up to the rated capacity, enabling fast and safe response when control is at risk.

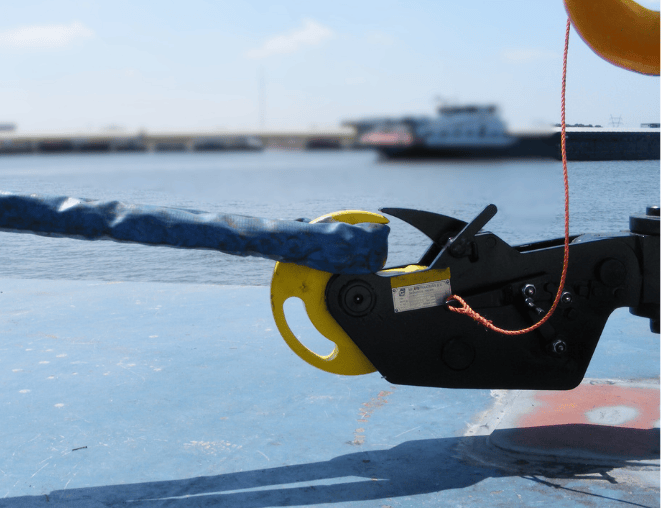

Quick release towing hooks type GSH

The Straatman Type GSH quick release towing hook supports safe and efficient towing operations across a wide range of vessels.

The hook operates manually using a lever or rope. The required operating force remains below 33 pounds, even at full safe working load. An integrated two-step release mechanism reduces the risk of accidental opening during use.

After release, the counterbalanced disc design allows quick and controlled manual resetting. Disc rotation during release limits energy impact and improves overall safety during towing operations.

The GSH towing hook is available with safe working loads ranging from 15 to 100 tonnes, making it suitable for different vessel types and towing requirements.

Configuration and Options

Straatman configures quick release towing hooks to match vessel layout and operational requirements. Available options include:

- Spring-loaded shock absorber

- Customised hook designs

- Local hydraulic or pneumatic release

- Remote-controlled release

- Load monitoring systems

- Hook foundations, brackets or towing posts

This modular approach allows the hook to integrate smoothly into different vessel configurations.

Testing of quick release towing hooks

Straatman tests every quick release towing hook at its own facility using calibrated hydraulic testing equipment with a capacity of 3,500 kN. This approach ensures consistent quality and verifiable performance before delivery.

First, disc-type towing hooks undergo a proof load test up to 200% of the specified Safe Working Load (SWL). For the GSH-100 model, Straatman applies a 150% SWL load test, in line with the hook’s design criteria.

Next, Straatman verifies the release function at safe working load. By doing so, the test confirms reliable, controlled operation of the release mechanism under realistic towing conditions.

Finally, if required, a classification authority selected by the client can witness the full testing process.

Special Designs and Project-Specific Solutions

In addition to standard configurations, Straatman supports project-specific towing hook designs.

Custom options include integrated foundations for direct welding to the vessel deck and hydraulic shock absorbers developed in cooperation with strategic partners. These solutions support improved load control and straightforward installation for demanding towing applications.

Quick release towing hook type GMH

The Straatman GMH quick release towing hook supports operations that require both mooring and towing functionality.

The GMH hook comes standard with a rope keeper, which enables safe and controlled use during towing. As a result, operators can switch between mooring and towing operations while maintaining full control and safety.

FREQUENTLY ASKED QUESTIONS

A quick release towing hook is a deck-mounted towing device used on tugboats and work vessels. During towing operations, the hook secures the towing line and releases it instantly when required, even under load. As a result, operators can respond immediately to changing conditions.

Unlike conventional towing hooks, a quick release towing hook enables controlled release from a safe position. Therefore, crews reduce manual handling on deck and maintain better control during both normal and emergency towing operations.

During towing operations, line loads can change suddenly due to vessel movement, weather or loss of control. A quick release towing hook allows the crew to release the towing line immediately when required.

This reduces the risk of capsizing, collision or damage to the vessel and improves overall crew safety.

A standard towing hook requires manual release and often cannot release the towing line under load. As a result, high line tension can create unsafe situations during towing operations.

In contrast, a quick release towing hook releases the towing line instantly and safely, even under high tension. This controlled release gives the crew a direct and reliable response during emergency situations.

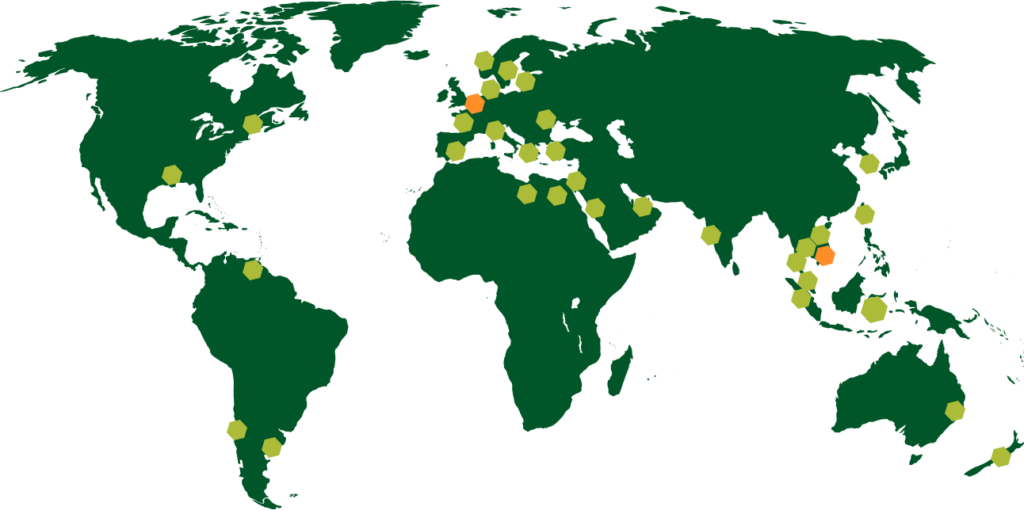

Tugboats, escort tugs, offshore support vessels, and port and harbour service vessels use quick release towing hooks during towing operations.

These vessels operate in conditions where towing loads change rapidly. Therefore, a fast and controlled release is essential for safe operation.

Yes. Straatman quick release towing hooks release the towing line while it remains under full tension, up to the hook’s rated capacity.

This capability plays a critical role during emergencies, when operators cannot gradually reduce line loads and must act immediately.

The Safe Working Load depends on the hook type and application. Straatman supplies quick release towing hooks with defined SWL ratings matched to the vessel type and towing operation. Typical applications range from moderate loads to high-capacity escort and offshore towing operations.

Key selection factors include:

– Required Safe Working Load

– Type of towing operation

– Release-under-load capability

– Safety features

– Certification requirements

– Integration with vessel layout and systems

Selecting the correct hook improves both safety and operational efficiency.

Yes. Straatman customises quick release towing hooks to match project requirements.

Options include capacity selection, control systems, release methods and integration with existing vessel systems.

With proper maintenance and correct operation, a quick release towing hook has a long service life, even in demanding marine and offshore environments

Download our Mooring & Berthing catalogue now

Our Mooring and Berthing Catalogue offers clear specifications, available options, and essential product insights.

LOOKING FOR THE RIGHT solution FOR YOUR PROJECT?

- High Quality Products

- Excellent Service

- Over 50 years of experience

- Certified on Every Level

es_ES

es_ES fr_FR

fr_FR pt_PT

pt_PT