Capstans

As an integral part of your quick release mooring hooks or separate custom-made capstans

Quick release mooring hooks enable safe and controlled mooring operations on jetties and terminals. Designed for daily use, they support reliable vessel mooring across a wide range of port and terminal applications.

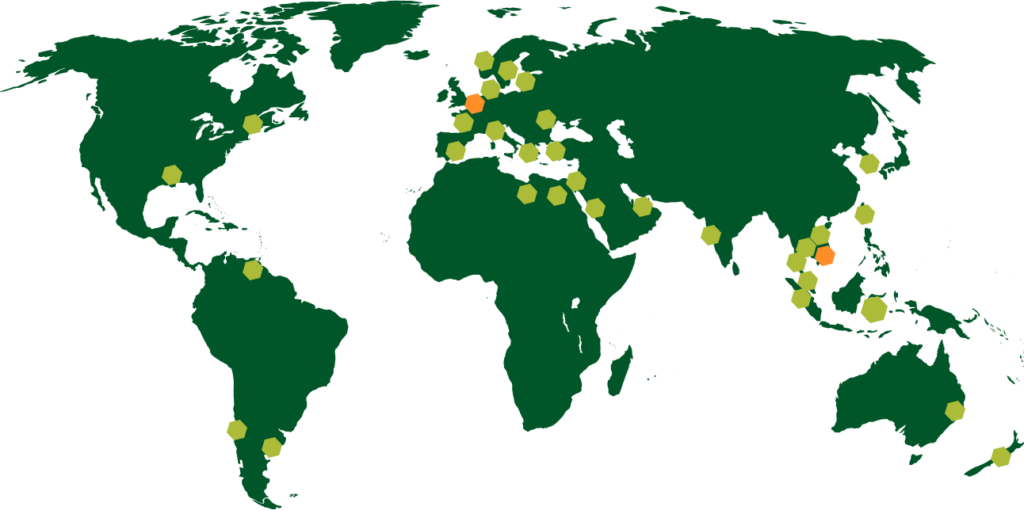

Straatman supplies mooring hooks for oil, gas, chemical, and bulk terminals worldwide, where controlled release and operational reliability are essential.

Our quick release mooring hooks are available in a range from 40 to 200 tons safely handling workloads (SWL) per hook. Typical mooring hook configurations are:

On request, we can design and produce customized quick-release mooring hook units based on specific requirements. For replacement projects, we adapt the hook design to fit existing anchor dimensions and bolt patterns.

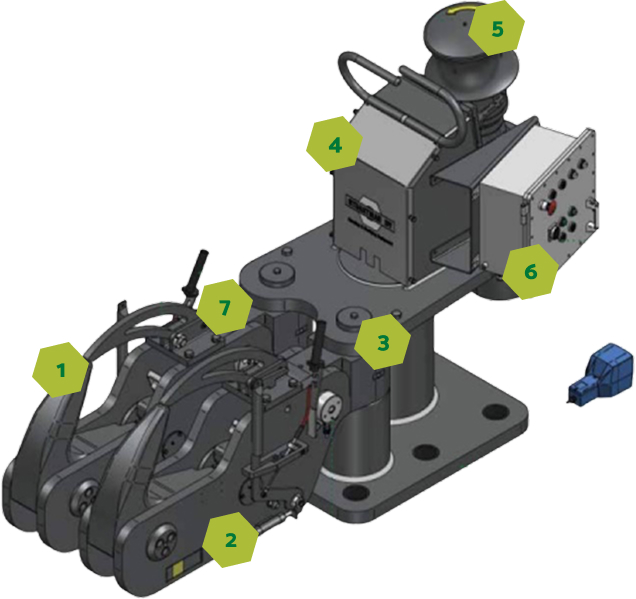

An example of our quick release mooring hooks including various options:

In some specific situations, there is a risk of the mooring rope slipping of the quick release hook. In order to avoid this risk a hook can be euiped with a rope keeper that prevents the rope from slipping

All quick release hooks can be equipped with an electric or electric-hydraulic release mechanism.

With inhook load cell calibration facility, locally and remote controlled by our MoorControl software.

All hooks are self supporting. All movements are limited to prevent contact with the structure.

The capstan allows hauling in of the mooring line in a safe and efficient way.

For hazardous zone, in conformance with ATEX, IECEx and Class 1 division 2.

The hook parts are made of forged steel and are counterbalanced.

The Straatman quick release mooring hook can be operated manually with minimal effort, even at full safe working load. To prevent accidental opening, a two-step release mechanism is used. After release, the hook can be reset manually through a simple rotational movement. During release, rubber blocks absorb energy, thereby reducing impact forces and protecting surrounding components

All hooks are tested in our own factory on our calibrated 3,500 kN hydraulic testing machine, and all test certificates will be issued as a part of the user manual and construction file. On request, a classification authority of your choice can witness the test.

We are your partner for your complete mooring system! We can integrate features such as: