Inspection, Maintenance and Spare Parts

Inspections and site surveys

We carry out on-site inspections to assess condition, risks, and remaining service life. Typical activities include:

- Visual inspection of mechanical components, structure, fasteners, and protective coatings

- Functional checks and operational tests

- Verification of settings and safety functions

- Check of wear parts and recommended replacement list

- Review of documentation and maintenance history (if available)

- Clear advice on repair, upgrade, or replacement options

You receive a practical report with findings, photos, and recommendations so you can plan maintenance and budget with fewer surprises.

Preventive maintenance

Preventive maintenance is planned work based on time or usage. It reduces unexpected failures and keeps equipment performing as intended. Depending on your system, this can include:

- Cleaning, lubrication, and adjustment

- Replacement of wear parts before failure

- Torque and fastening checks

- Function testing and verification

- Coating inspection and touch-up advice

Corrective maintenance and repairs

If something is damaged, stuck, or not working correctly, we can support fault-finding and repairs on-site. Where needed, we can advise the fastest safe workaround to keep operations moving until a full repair is completed.

Spare parts, upgrades, and refurbishments

We supply OEM spare parts for Straatman and other equipment and can propose upgrades to improve reliability, safety, or usability. We also support refurbishment projects where equipment can be restored instead of replaced.

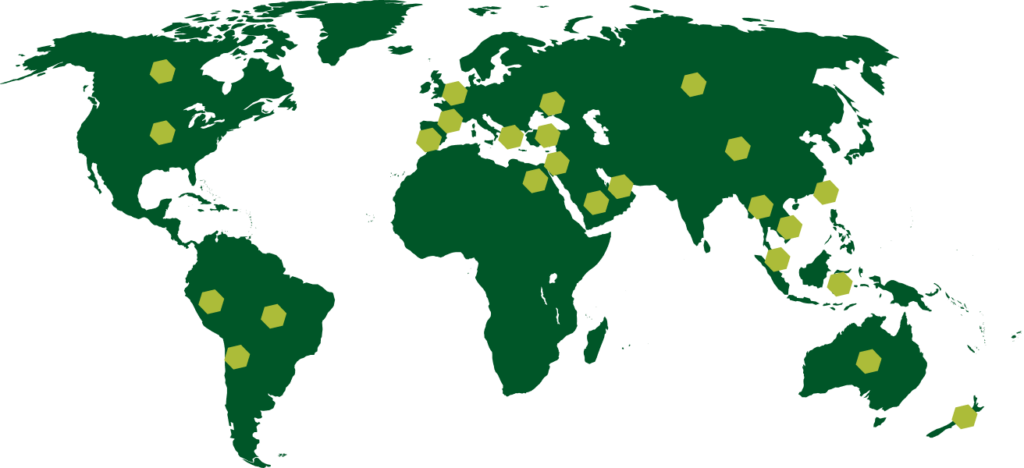

On-site support capabilities

Our service engineers can support you with:

Equipment inspections and repair planning

Site surveys to determine the best repair, upgrade, or maintenance approach—based on condition, usage, and operational constraints.

Quick Release Mooring Hook servicing

Inspection, overhaul support, functional tests, and advice on wear parts and replacement intervals.

Coating protection and corrosion control

Condition checks, recommendations for repair scope, and guidance for coating systems (including marine protection at critical areas).

Load monitoring system calibration. Checks, verification of readings, and support to keep data reliable.

Electrical and software fault diagnosis and repair

Troubleshooting of sensors, wiring, cabinets, power supply, and software-related issues (where applicable).

Support for Strainstall and AMTS hooks (and more)

Through our takeover agreement with Strainstall UK, we also service Strainstall and AMTS Quick Release Hooks and Berthing Aid Systems.

At the same time, our experience is not limited to these brands. We can inspect and maintain quick release mooring hooks and related equipment from any manufacturer. That includes inspection planning, servicing, troubleshooting, and maintenance advice. Also, when the original supplier is no longer available or response times are too long.

Maintenance contracts for long-term reliability

Maintenance contracts for long-term reliability

You can request a one-time inspection or repair visit, but for most terminals, a maintenance contract is the most effective option. A contract helps you plan costs, align maintenance with operational windows, and keep equipment in a known condition.

What a maintenance contract typically includes

- A service schedule (for example yearly, half-yearly, or based on usage)

- Inspection and functional testing

- Calibration checks where applicable

- Spare parts planning and recommended stock levels

- Reporting with clear actions and priorities

- Optional upgrades and improvement proposals

- Support for planning shutdown work and work permits (as required on site)

Benefits of planned maintenance

- More consistent equipment performance

- Earlier detection of safety risks and wear

- Fewer unplanned stoppages and call-outs

- Longer service life of critical mooring assets

- Better documentation for audits and internal reviews

does your mooring equipment need maintenance, inspection or upgrade?

- High Quality Products

- Skilled team of service engineers

- Excellent Service

- Certified on Every Level

es_ES

es_ES fr_FR

fr_FR pt_PT

pt_PT