Smart Bollard

Why a Smart Bollard?

Traditional bollards do not measure mooring loads. Ports rely on experience and assumptions during strong wind, current or wave conditions.

Loads that exceed safe limits can cause mooring lines to fail. Vessels may move away from the quay and create unsafe situations.

The Smart Bollard delivers accurate, real-time load data. Ports monitor actual mooring forces, improve safety and maintain continuous operational insight.

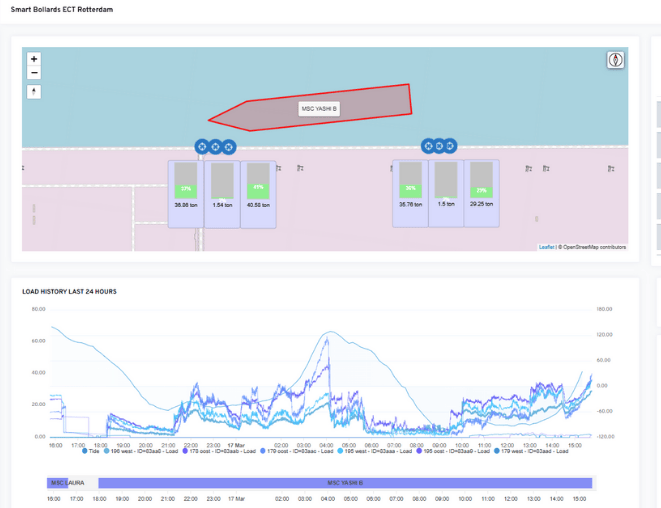

MoorControl platform

The MoorControl dashboard displays and logs:

- Load on the mooring line

- Line direction and angle

- Tide level

- Weather conditions

- Vessel history (using AIS data)

Administrators can manage users, configure alarm settings and integrate data into other systems through the application programming interface.

Data Connection

Smart Bollard Data Connection

The Smart Bollard connects easily to existing port infrastructure. The system supports both Ethernet and wireless communication. With an Ethernet connection, a compact switchbox sends all data directly to the cloud. For wireless installations, a local gateway provides a stable connection without additional cabling.

Cloud and application programming interface

The system processes all data securely in the cloud and makes it available through an online portal. Users can view real-time loads, weather conditions, currents and vessel information in one interface. The system integrates with other port systems via a standard application programming interface, ensuring data remains accessible across the entire operation.

Smart Bollard at your port

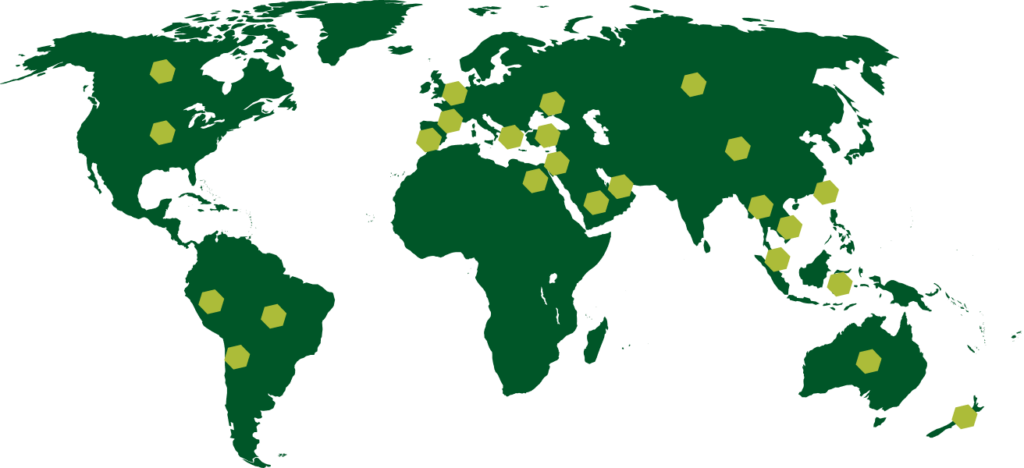

We developed the Smart Bollard in collaboration with the Port of Rotterdam. After a successful trial at the ECT Delta Terminal, we installed the system along the full ECT Delta quay.

Smart Bollards operate across the Port of Rotterdam, including the Amaliahaven. Major ports such as the Port of Antwerp and the MCS Terminal in Valencia also use the technology.

Interested in improving mooring safety and operational insight at your port?

Download the Smart Bollard whitepaper

Smart Bollard: Real-time Mooring Load Monitoring for Safer and Smarter Ports

Learn how real-time mooring load monitoring helps ports improve safety, reduce operational risk and optimise quay capacity.

FREQUENTLY ASKED QUESTIONS

The Smart Bollard improves safe mooring by measuring real-time loads on each mooring line. Increased tension caused by wind, current or passing traffic appears immediately in the online portal. Port teams see what is happening at the quay and can respond before a line becomes overloaded.

Ports gain safer berthing, fewer incidents and more control during docking operations.

Yes. The Smart Bollard is designed to integrate smoothly with existing port and terminal systems. All mooring load data is available through a standard Application Programming Interface, which allows ports to connect the Smart Bollard to their own dashboards, traffic systems or terminal software. This ensures that data from the bollard becomes part of the wider operational picture, supporting smarter decision-making across the port.

With the Smart Bollard, operators monitor mooring safety in real time. The system transmits data via an Ethernet cable or a wireless connection. Port authorities, terminal operators and vessel operators access the data in clear graphic and digital formats. The Smart Bollard processes all data in the Straatman MoorControl software. The cloud-based platform is accessible through any common web browser. A central dashboard provides all information needed to fully use the Smart Bollard.

Yes. We can install Smart Bollards on existing quays and anchor bolts.

Although integrating Smart Bollards into a new quay is the most straightforward option, our engineering team also installs them on existing infrastructure. We recently applied this approach at the new Prinses Amaliahaven in Rotterdam. In most projects, Smart Bollards replace existing bollards. Our engineers select the best installation method for each situation to ensure a proper and reliable fit.

Every project is unique, and we tailor the Smart Bollard to meet your specific needs, including cabling. If cabling is a challenge, we also explore solar-powered options. Our experience with solar systems as an alternative to traditional cabling has proven highly valuable. One of our clients is successfully using a solar setup. Also, the use of battery packs is a good alternative solution

When multiple mooring lines are attached, the Smart Bollard measures the total load acting on the bollard. In this situation, the system does not calculate individual line loads. Instead, it provides clear insight into the combined forces applied to the bollard structure.

The Smart Bollard uses a specific geometry that guides mooring lines upward as load increases. As a result, the line naturally moves to the top of the bollard under tension. This allows the system to measure the applied force accurately and consistently.

The Smart Bollard looks and functions like a standard bollard but adds real-time load measurement. Integrated sensors measure mooring line loads by detecting and translating structural movement caused by line tension. Port authorities, terminal operators and vessel operators access the measured data in real time.

At the Port of Rotterdam, we installed 6 pieces of Smart Bollards at ECT Delta Terminal and 108 pieces at Prinses Amaliahaven. Besides these Dutch ports, we installed Smart Bollards at the Port of Antwerp and the MSC Terminal in Valencia.

The Smart Bollard has undergone extensive testing. Read our Smart Bollard White Paper to learn more about all the steps and tests that we have gone through to get the most accurate measurements from the Smart Bollard.

Yes. Contact us to discuss the options!

do you want to run a smart bollard trial at your port?

- Real-time insights into mooring loads

- Improved safety

- Higher operational efficiency

- Reduced costs

es_ES

es_ES fr_FR

fr_FR pt_PT

pt_PT